Project description

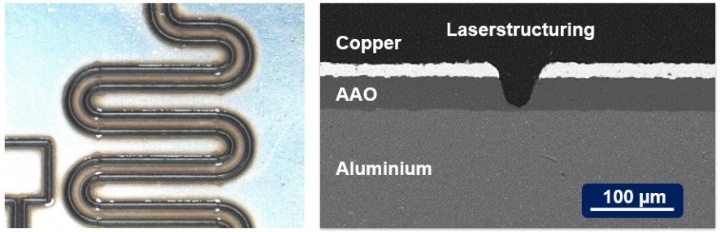

The trend towards ever higher power densities with simultaneously smaller installation space in power electronics applications imposes ever-increasing challenges on the thermal management. The thermal path must dissipate the heat resulting from power loss via the lowest possible thermal resistance while simultaneously insulating electrical components from the cooling system. This limits the maximum power despite high efficiencies. The present project focuses on the process chain-based testing and characterization of a novel insulating metal substrate (IMS) variant with ceramic anodized layers as dielectric and aluminum as basic substrate. Compared to conventional DBC-based counterparts, this technology has the advantage of adaptability on independent geometric structures which also includes 3D structures as well as direct processing on the heatsink omitting the thermal bottleneck of the thermal insulating material (TIM). Furthermore, the insulation layer offers potential for use at high temperatures of up to 200°C. In addition to mechanical characterizations such as adhesive strength and surface roughness, the insulating structures of the new anodized ceramics process will be characterized in the stress field between minimum thermal resistance and maximum dielectric strength under the influence of temperature. At the end of the project, a functional demonstrator in the form of a DC-DC converter with integrated temperature and current sensors is to be developed, including a comparison to prior art based on conventional die mounting, to show the possibilities for use in power electronics applications. With this proposal the involved project partners address the topics “High Performance Substrates, Packaging and Interconnection Technologies for High Power/High Temperature Applications” and “Reliability and Robustness”.

Project partner

-

Institute of Robust Power Semiconductor Systems (ILH)

- Hahn Schickard Stuttgart

Contact

Dominik Koch

M.Sc.Group Leader Power Electronics / Research Assistant

Ingmar Kallfass

Prof. Dr.-Ing.Institute Director