Open student thesis

Sensing is a major part of smart objects and equipment, for example, condition monitoring for predictive maintenance, which enables context awareness and production performance improvement, and results in a drastic decrease in downtime due to preventive maintenance.

In the framework of this thesis, an AI data framework monitoring framework is to be implemented using the FP-AI-MONITOR2 framework from STMicroelectronics. The software needs to be adapted to our own microcontroller board and sensor nodes.

Tasks & Goals

- familiarization & literature search

- analysis of the FP-AI-MONITOR2 and AI related software

- adaptation of the microcontroller source code for a custom board

- scientific verification & validation of the design

- written thesis & presentation

Previous Knowledge

- Power Electronics I/II lecture or similar

- Knowledge of ARM microcontroller programming in C helpful

- Strong interest in AI

Start: immediately

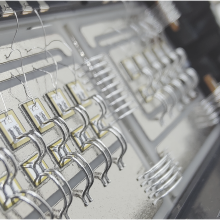

In the evolving electric vehicle market there is a need for high efficient and reliable power electronics. While Silicon existed in the market for several decades and sophisticated life time models like LESIT or CIPS08 were developed for those components such knowledge is still lacking limited applicable for SiC due to the different technology and physics. In this overall project a 3-phase inverter should be developed which provides close to application stresses. Sensor systems and highly accelerated tests as well as safety measurements should be developed. A focus on subtask is pursued and will be discussed with the tutor prior of the work.

Contact

Dominik Koch

M.Sc.Group Leader Power Electronics / Research Assistant

Benjamin Schoch

M.Sc.Research Assistant